La manufactura en Estados Unidos tiene las máquinas CNC como uno de sus elementos vitales. Revolucionando industrias, desde la aeroespacial hasta la automotriz, desde los dispositivos médicos hasta la electrónica, la defensa y las herramientas de precisión, el CNC constituye la columna vertebral de la producción de alta precisión y gran volumen.

Estados Unidos es uno de los países con mayor arraigo en el mecanizado CNC. Además, cuenta con la ventaja de la instalación de motores, innovaciones en automatización y estrictos estándares de calidad. Fabrica máquinas CNC con características de precisión, escalabilidad, materiales avanzados y sistemas de producción automatizados.

La forma más efectiva de elegir la El mejor fabricante de máquinas CNC de EE. UU. es considerar cómo esa máquina impactará la precisión del mecanizado, la productividad, la confiabilidad operativa y la eficiencia de fabricación a largo plazo. La siguiente guía incluye las 14 principales Fabricantes de máquinas CNC en EE. UU., junto con sus capacidades, fortalezas e idoneidad para diferentes requisitos industriales.

| Marca | Año de fundación | Sede | Características |

| Milltronics | 1973 | Indiana, Estados Unidos | El control CNC patentado INSPIRE ofrece un rendimiento confiable y soluciones rentables para entornos de mecanizado de producción y de taller de herramientas. |

| Kent CNC | 1979 | California, Estados Unidos | Máquinas CNC de servicio pesado, estructuras de máquinas rígidas, estabilidad a largo plazo y aplicaciones de mecanizado de producción. |

| Fadal | 1973 | Illinois, Estados Unidos | Construcción robusta de tipo caja, compatibilidad con versiones anteriores, sólida cobertura de garantía e ingeniería impulsada por maquinistas. |

| Industrias Owens | 1944 | Wisconsin, Estados Unidos | Mecanizado CNC de precisión, fabricación de componentes complejos, calidad de producción constante, soporte multiindustrial y mecanizado de alta tolerancia. |

| CNC YANGSEN EE.UU. | 2003 | EE.UU | Centros de mecanizado CNC, soluciones listas para automatizar, estructuras de máquinas rígidas, construcciones personalizables, resultados de fabricación centrados en la mejora del rendimiento. |

| Maquinaria especializada Inc. | 1983 | EE.UU | Máquinas CNC personalizadas, diseño personalizado específico para la aplicación, integración de automatización, soluciones de fabricación diseñadas y enfoque en la optimización de procesos. |

| Máquinas mejor construidas | 2010 | EE.UU | Máquinas CNC de alta resistencia, ingeniería orientada a la precisión, sostenibilidad a largo plazo y compatibilidad con la fabricación industrial. |

| Hardinge | 1980 | Nueva York, Estados Unidos | Soluciones de torneado y rectificado de precisión |

| Automatización Hass | 1983 | California, Estados Unidos | Máquinas CNC económicas para uso diario en pymes y educación. |

| Takumiusa | 1966 | Míchigan, Estados Unidos | Fabricación CNC a gran escala, producción habilitada para automatización, infraestructura de fabricación global y capacidad de volumen extraordinaria. |

| CNC avanzado | 1987 | Ohio, Estados Unidos | Servicios de mecanizado de precisión CNC, sistemas orientados a la producción, calidad de salida constante y experiencia en mecanizado industrial. |

| Tormach | 2001 | Madison, Estados Unidos | Máquinas CNC rentables, perfectas para actualizaciones modulares, software de control de código abierto y ofrecen piezas mecanizadas flexibles para creación de prototipos. |

| Tecnologías de fabricación de BDE | 1986 | Oregón, Estados Unidos | Tecnologías de mecanizado y fabricación CNC, ingeniería de precisión, soluciones de producción escalables y confiabilidad industrial. |

| Tecnologías de unión superiores | 1992 | Illinois, Estados Unidos | Soluciones de mecanizado y unión CNC que consisten en procesos de fabricación avanzados, producción de componentes de alta resistencia y aplicaciones industriales. |

Tipo de asunto:Fabricante de Fresadoras CNC, máquinas de torneado CNCy sistemas de control CNC propietarios.

Ubicación:EE.UU

Año de fundación:1973

Introducción del fabricante:

Milltronics es un fabricante de máquinas CNC con sede en Estados Unidos. Más de 50 años de experiencia en el diseño y producción de máquinas fresadoras y torneadoras CNC.

La empresa ha instalado más de 14.000 máquinas en todo el mundo y opera desde su sede en Indianápolis, Indiana, atendiendo a clientes en América del Norte y mercados internacionales a través de distribuidores y socios de servicio.

Milltronics es reconocido por su desarrollo interno de control CNC, incluida la plataforma de control INSPIRE CNC, y apoya a industrias como Mecanizado de precisión aeroespacial, automotriz, de defensa, médico y general..

Ámbito de negocio:

• Centros de mecanizado verticales CNC

• Tornos CNC

• fresadoras de herramientas

• Fresadoras de puente y sistemas de control CNC patentados

Razón recomendada:

Milltronics se recomienda a los fabricantes que buscan máquinas CNC fabricadas en Estados Unidos con tecnología de control integrada, sólido soporte de servicio y una larga trayectoria en aplicaciones de mecanizado de producción y de sala de herramientas.

Tipo de asunto:Fabricante de centros de mecanizado y torneado CNC con soluciones de automatización avanzadas.

Ubicación:Míchigan, Estados Unidos

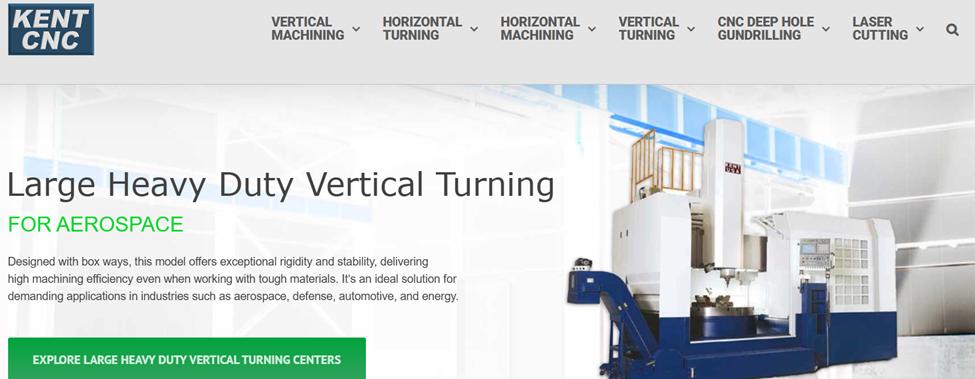

Año de fundación:1979

Introducción del fabricante:

Kent CNC ha estado suministrando máquinas herramienta a los mercados globales. desde 1979, con más de 24.000 máquinas Vendido en todo el mundo.

La empresa se centra en soluciones CNC avanzadas, que incluyen centros de mecanizado de 5 ejes, grandes máquinas de pórtico, centros de torneado multitarea y sistemas integrados de automatización.

Kent CNC apoya a sus clientes a través de una red de distribuidores establecida en todo Estados Unidos y regiones internacionales seleccionadas.

Presta servicios a industrias como la aeroespacial, la energética, la automotriz, la de defensa y la fabricación industrial pesada.

Ámbito de negocio:

•Centros de mecanizado verticales y horizontales CNC

•Torno CNC y rectificadoras CNC

•Máquinas de perforación de pozos profundos

•Sistemas de corte por láser

Razón recomendada:

Kent CNC es muy valorado por los fabricantes que requieren soluciones de mecanizado complejas, máquinas de gran capacidad y sistemas CNC listos para la automatización respaldados por un sólido servicio posventa y experiencia en ingeniería de aplicaciones.

Tipo de asunto:Fabricación de centros de mecanizado verticales asequibles, confiables y fáciles de usar para la creación de prototipos en múltiples industrias.

Ubicación:Florida, Estados Unidos

Año de fundación: 1973

Introducción del fabricante:

Fadal es un fabricante de máquinas CNC de América del Norte con más de 50 años de experiencia.

Mantiene una red de distribuidores y servicios en los Estados Unidos y Canadá, brindando ventas regionales, asistencia técnica y disponibilidad de repuestos.

Fadal diseña y construye centros de mecanizado CNC rentables y fáciles de usar, diseñados por maquinistas experimentados para lograr confiabilidad a largo plazo.

Estas máquinas se utilizan comúnmente en muchas industrias de relojería, como la automotriz, la aeroespacial, la médica, la de creación de prototipos, la de matrices y moldes, así como el mecanizado de precisión en general.

Ámbito de negocio:

•Centros de mecanizado verticales CNC

•Fresadoras de 3 y 5 ejes

•Soluciones de prototipado y mecanizado de producción

•Integración de controladores y soporte CNC industrial

Razón recomendada:

Si busca máquinas CNC estadounidenses económicas, fiables y de rendimiento comprobado, Fadal es una excelente opción para los fabricantes. Las máquinas son fáciles de operar, cuentan con redes de servicio bien respaldadas y se adaptan tanto a entornos de producción como de prototipado.

Tipo de asunto:Fabricante de mecanizado CNC de precisión para componentes industriales complejos.

Ubicación:Wisconsin, Estados Unidos

Año de fundación:1944

Introducción del fabricante:

Owens Industries, una empresa de mecanizado CNC de precisión ubicada en EE. UU., fue... fundada en 1944 y tiene su principal planta de fabricación en Oak Creek, Wisconsin.

La empresa presta servicios a clientes en todo Estados Unidos con gestión de proyectos nacionales, soporte de ingeniería y servicios de fabricación de precisión.

Desde sus modernas instalaciones de mecanizado CNC, Owens Industries proporciona componentes con tolerancias ultra ajustadas utilizando la mejor maquinaria alemana y suiza.

Las soluciones de fabricación que ofrece se han utilizado en los sectores aeroespacial, de defensa, médico, energético, óptico y otros sectores industriales de alta precisión.

Ámbito de negocio:

• Mecanizado CNC de precisión de componentes complejos

• Centros de mecanizado multieje

• Soluciones de mecanizado orientadas a la producción

• Servicios de fabricación industrial con capacidad de tolerancia estricta

Razón recomendada:

Owens Industries es una opción recomendada para fabricantes que requieren alta precisión, rendimiento repetible y una producción consistente en la producción de componentes complejos. Su experiencia garantiza la fiabilidad en aplicaciones industriales críticas.

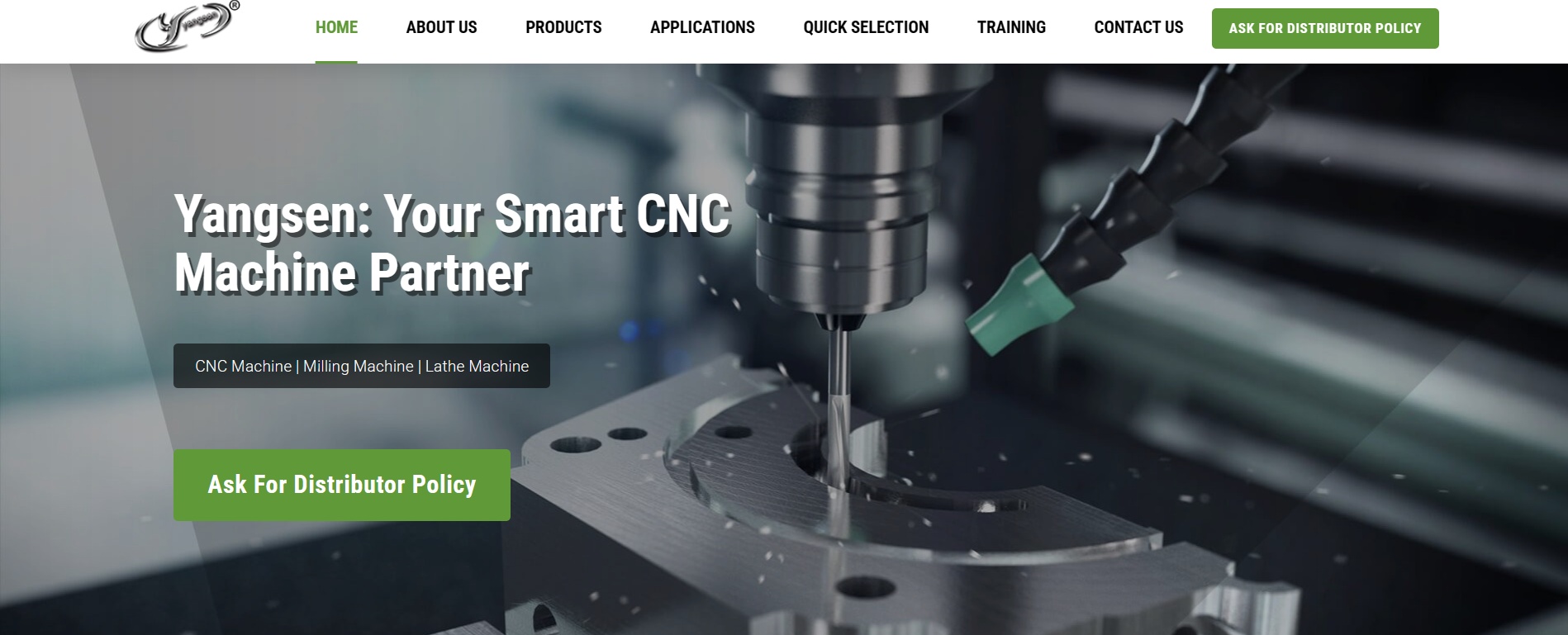

Tipo de asunto:Fabricante de centros de mecanizado CNC personalizados con soluciones preparadas para la automatización

Ubicación:EE.UU

Año de fundación:2003

Introducción del fabricante:

Fundada en 2003, CNC YANGSEN fabrica máquinas CNC diseñadas a medida para la producción industrial.

Yangsen crea más de 5.000 máquinas CNC cada año para una variedad de OEM, distribuidores y fabricantes industriales globales que necesitan soluciones que puedan ampliarse.

CNC YANGSEN asegura que cada máquina suministrada ha sido fabricada con precisión, uniformidad, exactitud y confiabilidad.

Habiendo acumulado Más de 100 patentes y con una huella de exportación que abarca más de 20 paísesYangsen demuestra creatividad y un amplio atractivo internacional.

La marca garantiza un paquete completo con entregas rápidas, servicio posventa completo y total confidencialidad.

Ámbito de negocio:

• centros de mecanizado de 5 ejes

• Centros de mecanizado CNC verticales

• Tornos CNC y centros de mecanizado de doble columna

• Automatización personalizable

•Centros de mecanizado CNC horizontales

• Soluciones CNC llave en mano

Razón recomendada:

CNC YANGSEN es la mejor opción para fabricantes que buscan sistemas CNC flexibles y listos para la automatización. Sus máquinas están diseñadas para una estabilidad operativa a largo plazo y versatilidad para diversas aplicaciones industriales.

Tipo de asunto:Fabricante de maquinaria CNC personalizada para producción específica de la aplicación

Ubicación:EE.UU

Año de fundación:1983

Introducción del fabricante:

Specialty Machinery Inc., con más de 40 años de experiencia, es un proveedor líder de soluciones CNC con sede en Grand Rapids, Michigan, con una instalación adicional en Suwanee, Georgia.

Specialty Machinery apoya a clientes de todo el país a través de una sólida red de personal de ventas, servicio y soporte técnico, lo que garantiza capacidad de respuesta y el máximo tiempo de actividad.

Specialty Machinery se asocia con marcas líderes en la industria como Kimla y Vicla para ofrecer máquinas CNC avanzadas, incluidos láseres de fibra, prensas plegadoras, enrutadores CNC y máquinas de corte.

Sus soluciones están diseñadas para mejorar la productividad, la precisión y la rentabilidad de los fabricantes de todos los tamaños en las industrias de fabricación de metales, carpintería, embalaje y compuestos.

Ámbito de negocio:

• Maquinaria CNC diseñada a medida

• Diseño de máquinas específicas para cada aplicación

• Soluciones de integración de automatización

• Sistemas de producción CNC optimizados para procesos

Razón recomendada:

Specialty Machinery Inc. es la opción ideal para un fabricante que necesita soluciones CNC altamente personalizadas. Sus diseños específicos para cada aplicación mejoran la eficiencia del flujo de trabajo y facilitan la integración de la automatización en procesos de producción especializados.

Tipo de asunto:Empresa fabricante de máquinas CNC industriales especializada en robustez y precisión.

Ubicación:EE.UU

Año de fundación:2010

Introducción del fabricante:

Desde 2010, BBM ha dejado su huella en Shelbyville, Kentucky, proporcionando fresadoras y sierras CNC para corte de piedra con un enfoque en la durabilidad y la facilidad de uso.

Manteniendo una sólida red nacional de ventas, servicio y repuestos, BBM apoya a los fabricantes de piedra en todo Estados Unidos.

Las acciones de la empresa más de un millón de dólares valor de las piezas disponibles para envío al día siguiente y brinda servicio, tanto de forma remota como en el sitio del cliente, mediante el uso de sus técnicos experimentados.

Las máquinas BBM PALADIN, DEFENDER y DOMINATOR han sido diseñadas para ser precisas y confiables con un mantenimiento mínimo para que los fabricantes puedan optimizar y mejorar la productividad y la eficiencia dentro de sus operaciones.

Ámbito de negocio:

• Máquinas CNC industriales

• Soluciones de mecanizado de precisión

• Orientado a sistemas de producción

• Entorno operativo a largo plazo

• Apoyo a la fabricación industrial

Razón recomendada:

Better Built Machines es altamente recomendable para fabricantes industriales que buscan máquinas CNC robustas y precisas, diseñadas para un funcionamiento continuo. Ofrecen estabilidad a largo plazo y una precisión de mecanizado constante.

Tipo de asunto:Fabricante de máquinas CNC y sujeción de precisión

Sede:EE.UU

Año de fundación:1890

Introducción del fabricante:

Fundada en 1890 y ubicada en Elmira, Nueva York, Hardinge se especializa en centros de torneado CNC de precisión, rectificadoras y soluciones de sujeción.

La empresa apoya a fabricantes de todo el mundo con una red de ventas de productos, servicios y operaciones tecnológicas en Estados Unidos, Suiza, Taiwán y Asia.

El proceso de trabajo integrado de Hardinge garantiza que las máquinas y las soluciones de sujeción funcionen juntas sin problemas, maximizando la eficiencia, la precisión y la productividad para los clientes de todo el mundo.

Con Más de 130 años de experiencia en mecanizadoLa empresa ofrece soluciones de corte de metales ultraprecisas, estables y confiables para las industrias aeroespacial, médica, de herramientas y de fabricación de alta precisión.

Ámbito de negocio:

• Centros de torneado CNC

• Rectificadoras de precisión

• Centros de mecanizado verticales y horizontales

• Soluciones de sujeción y herramientas

Razón recomendada:

Hardinge es ideal para fabricantes que buscan mecanizado de precisión y rectificado de alta precisión, con una solución de sujeción integrada. Su siglo de experiencia garantiza un rendimiento en industrias críticas.

Tipo de asunto:Fabricación de máquinas herramienta CNC asequibles y fáciles de utilizar.

Ubicación:EE.UU

Año de fundación:1983

Introducción del fabricante:

Haas Automation fue fundada en 1983 y está ubicada en Oxnard, California. Haas es experta en centros de mecanizado verticales y horizontales, tornos CNC, mesas giratorias y máquinas especiales.

La empresa suministra a fabricantes de todo el mundo máquinas-herramientas CNC y soluciones de automatización de alta calidad y precisión.

Con fabricación propia de todos los componentes importantes y un 1Instalación de última generación de 0,1 millones de pies cuadradosHaas ofrece precisión, durabilidad y rentabilidad excepcionales.

Sus prácticas de producción ajustada y justo a tiempo permiten una entrega rápida y un valor excepcional para el cliente.

Haas es un socio confiable para talleres de todos los tamaños que buscan soluciones CNC confiables y fabricadas en Estados Unidos.

Ámbito de negocio:

• Centros de mecanizado verticales CNC

• Centros de mecanizado horizontales CNC

• Centros de torneado y tornos CNC

• Soluciones de mecanizado de 5 ejes

• Mesas giratorias y sistemas de automatización

• Soluciones de formación y educación en CNC

Razón recomendada:

Se recomienda Haas Automation a aquellos fabricantes que desean máquinas CNC más asequibles, confiables y fáciles de usar, junto con un sólido soporte local y una amplia cobertura de distribuidores en toda América del Norte.

Tipo de asunto:Fabricante de centros de mecanizado y tornos CNC de alta precisión.

Ubicación:Míchigan, Estados Unidos

Año de fundación:1966

Introducción del fabricante:

Más de 30 años Takumi USA ha suministrado soluciones CNC de alto rendimiento. Fue adquirida por Hurco Companies en 2015.

Takumi combina la probada tecnología de control FANUC con diseños de máquinas resistentes y confiables.

Takumi cuenta con el respaldo de la red de soporte de larga data de Hurco, que brinda experiencia local y un servicio receptivo en toda América del Norte.

Estas máquinas están diseñadas teniendo en cuenta la precisión, la durabilidad y el rendimiento de alta velocidad para los sectores aeroespacial, automotriz, médico y de fabricación de herramientas y matrices como usuarios finales.

Ámbito de negocio:

• Centros de mecanizado verticales y horizontales CNC

• Tornos CNC y soluciones de mecanizado multieje

• Centros de mecanizado CNC de 5 ejes para piezas complejas

• Soluciones de sondeo, inspección y automatización en máquina

Razón recomendada:

Takumi es ideal para fabricantes que buscan precisión, velocidad, durabilidad y asequibilidad. Cuenta con más de 30 años de experiencia y está respaldado por la consolidada red de servicio de Hurco, lo que garantiza precisión continua, mínimos tiempos de inactividad y rendimiento incluso en las industrias más exigentes, con el máximo retorno de la inversión en CNC.

Tipo de asunto:Fabricante de mecanizado CNC de precisión para industrias centradas en la producción.

Ubicación:Ohio, Estados Unidos

Año de fundación:1987

Introducción del fabricante:

Fundada en 1987CNC Machining cuenta con un alto grado de automatización en su taller de producción. La empresa, ubicada en el centro de Ohio, se especializa en el mecanizado de aluminio de alta velocidad de 4 y 5 ejes.

La empresa, que presta servicios a fabricantes en todo Estados Unidos, combina automatización avanzada, herramientas especializadas y equipos de precisión, incluidas máquinas Makino, para ofrecer plazos de entrega rápidos, calidad constante y producción confiable a escala.

Registrado en ITAR y certificado ISOAdvance CNC es reconocido por su compromiso con la precisión, la satisfacción del cliente y las soluciones de mecanizado innovadoras para producciones de volumen medio a alto.

Ámbito de negocio:

• Mecanizado CNC de precisión

• Sistemas de mecanizado orientados a la producción

• Apoyo a la fabricación industrial

• Mecanizado de calidad constante

• Producción con tolerancias estrictas

• Apoyo a las necesidades de producción industrial en curso

Razón recomendada:

Advance CNC es la mejor opción para fabricantes que buscan precisión constante y un rendimiento de mecanizado estable, lo que le otorga el máximo reconocimiento. Sus soluciones CNC garantizan calidad y fiabilidad repetibles en entornos de producción.

Tipo de asunto:Fabricante de máquinas CNC asequibles y soluciones de automatización modular.

Ubicación:Madison, Estados Unidos

Año de fundación:2001

Introducción del fabricante:

La empresa fue fundada en 2001, ofreciendo diseños y soporte de Capaz, asequible y fácil de usar Fresadoras CNC, tornos, enrutadores y sistemas de automatización alimentados por energía monofásica estándar.

Tormach es un fabricante estadounidense de maquinaria CNC y herramientas de automatización, con sede en Madison, Wisconsin. Tormach atiende a clientes de todo el mundo.

Las máquinas Tormach están diseñadas para ser modulares y actualizables, de modo que se puedan agregar o cambiar capacidades sin necesidad de bloqueos de software o contratos de servicio.

Tormach ofrece soluciones confiables en tecnología CNC en un amplio espectro de materiales para fabricantes, educadores e innovadores.

Ámbito de negocio:

• Fresadoras CNC

• Tornos CNC

• Fresadoras CNC

• Soluciones de automatización y actualización

• Paquetes educativos de máquinas CNC

• Software de control CNC de código abierto

Razón recomendada:

Tormach se recomienda para pequeños fabricantes, talleres de creación de prototipos y usuarios educativos que buscan máquinas CNC asequibles, actualizaciones flexibles y propiedad total de las máquinas, con soporte confiable desde los Estados Unidos.

Tipo de asunto:Proveedor de soluciones tecnológicas de fabricación y mecanizado CNC

Ubicación:Oregón, Estados Unidos

Año de fundación:1986

Introducción del fabricante:

Tecnologías de fabricación de BDE Comenzó en 1986, que sirve para apoyar la fabricación CNC de precisión.

BDE Manufacturing Technologies, ubicada a la vuelta de la esquina de Portland, Oregón, es un moderno taller de máquinas CNC de última generación.

Fundada por Bob y Rick Hale, BDE combina décadas de experiencia con tecnología avanzada para brindar soluciones de precisión de fresado CNC, trabajo de torno, herramientas, creación de prototipos y ensamblaje.

Con una superficie construida de 34.500 pies cuadradosLa instalación cuenta con personal altamente capacitado en un entorno de diseño totalmente conectado en red que les permite trabajar en proyectos.

Ámbito de negocio:

• Soluciones de mecanizado CNC

• Tecnologías de fabricación de precisión

• Sistemas de producción escalables

• Servicios de mecanizado industrial

• Mecanizado de salida consistente

• Soluciones de soporte a la fabricación

Razón recomendada:

BDE Manufacturing Technologies es ideal para fabricantes que buscan soluciones CNC escalables. Su enfoque centrado en la producción facilita un mecanizado adaptable y fiable para diversas necesidades de fabricación industrial.

Tipo de asunto:Proveedor de soluciones avanzadas de mecanizado CNC y unión

Ubicación:Illinois, Estados Unidos

Año de fundación:1992

Introducción del fabricante:

SJTI se especializa en soldadura precisa y mecanizado CNC, donde Excellent Joining Technologies, Incorporated, se estableció en tal profesión. en 1992.

Pudo desarrollar habilidades en soldadura TIG, soldadura microláser, mecanizado CNC de 5 ejes, corte láser y fabricación aditiva.

Es Certificación AS9100 e ISO 9001, registrado en ITAR, certificado por la FAA y es un Empresa propiedad de mujeres, con servicios orientados a la creación de prototipos y a la producción tanto de bajo como de alto volumen, así como a necesidades de fabricación complejas.

SJTI presta servicios a clientes de los sectores aeroespacial, militar e industrial. SJTI combina tecnologías avanzadas con 30 años de experiencia para ofrecer piezas, herramientas y ensambles de alta precisión.

Ámbito de negocio:

• Soluciones de mecanizado CNC

• Tecnologías de unión avanzadas

• Producción de componentes de alta resistencia

• Sistemas de fabricación industrial

• Servicios de mecanizado de precisión

• Soluciones orientadas a la producción

Razón recomendada:

Superior Joining Technologies es la opción ideal para fabricantes que buscan sistemas CNC con capacidades de unión avanzadas. Su experiencia garantiza la producción fiable de componentes de alta resistencia para aplicaciones industriales exigentes.

¿Son las máquinas CNC adecuadas para la producción industrial a gran escala?

Sí, las máquinas CNC industriales en EE. UU. están diseñadas para funcionar de forma continua durante largos periodos de producción. Mantienen la misma precisión y rendimiento en todo momento, por lo que se utilizan tanto en la producción en masa como en entornos de fabricación con un alto nivel de exigencia industrial.

¿Es posible personalizar las máquinas CNC para requisitos de producción específicos?

La mayoría de los fabricantes de CNC en EE. UU. ofrecen opciones de personalización de husillos, infraestructura de automatización, sistemas de herramientas, tamaño de la máquina y compatibilidad del software para satisfacer necesidades de producción específicas.

¿Qué industrias se benefician más del mecanizado CNC en EE.UU.?

Las industrias más beneficiadas incluyen la aeroespacial, la automotriz, la defensa, los equipos médicos, la electrónica, el petróleo y el gas, las herramientas y la fabricación de metales, específicamente porque existe una gran demanda de precisión, repetibilidad y complejidad en la fabricación de componentes.

¿Son confiables las máquinas CNC fabricadas en EE.UU.?

Sí, todas las máquinas CNC fabricadas o suministradas en EE. UU. siguen estrictos estándares de ingeniería y calidad y son reconocidas mundialmente por su durabilidad y confiabilidad, no solo por la automatización avanzada que pueden manejar sino también por el amplio espectro de industrias a las que se aplican.

¿Qué factores deben tenerse en cuenta antes de seleccionar un fabricante de CNC en EE.UU.?

Entre los factores importantes están la precisión de la máquina, la calidad de la máquina, la preparación para la automatización, la capacidad de producción, el servicio postventa, las certificaciones en la industria, la experiencia técnica y la experiencia en aplicaciones similares por parte del fabricante.

¿Cómo mejora la automatización la eficiencia del mecanizado CNC?

Una mayor productividad a través de una menor intervención manual, tiempos de ciclo más cortos, preservación de una calidad constantemente alta, disponibilidad para operaciones no tripuladas y mejora de la seguridad general en entornos industriales es la eficacia con la que la automatización mejora la eficiencia del CNC.

La industria de fabricación CNC en Estados Unidos continúa avanzando gracias a la innovación, la automatización y la ingeniería de alta precisión. Los principales fabricantes de máquinas CNC ofrecen servicios en los sectores aeroespacial, automotriz, médico e industrial. Los fabricantes de máquinas CNC adecuados para una empresa dependen de sus objetivos de producción, requisitos de precisión, escalabilidad e incluso del servicio posventa.

Para la fabricación CNC de precisión que busca, CNC Yangsen ofrece soluciones de mecanizado CNC y tratamiento de superficies confiables y capaces específicas para las necesidades de su aplicación.