¿Alguna vez te has preguntado qué proceso es mejor para tu proyecto Die Casting Vs? ¿Mecanizado CNC? Las personas a menudo quedan atrapadas cuando ambos enfoques tienen una variedad de beneficios que los hacen atractivos. Elegir el método incorrecto puede provocar retrasos, mayores costos y mala calidad del producto. Si ha tenido problemas con cuál de los dos métodos será mejor para usted, no se preocupe, ya que esta guía le aclarará la confusión.

Los principales factores que definen la decisión entre la fundición a presión y el mecanizado CNC son la cantidad de producción, el material y la precisión. Mientras que la fundición a presión es óptima para aplicaciones de gran volumen donde las piezas son relativamente grandes y contienen formas intrincadas. El mecanizado CNC es más adecuado para cantidades más pequeñas, formas complejas y tolerancias más estrictas. Le ayudará a determinar qué método es adecuado para su proyecto una vez que sepa lo que requiere su proyecto.

Ahora toca ampliar la información relativa a cada uno de estos procesos. En los siguientes subtemas, se realizará una comparación entre la fundición a presión y el mecanizado CNC en aspectos como el costo, la velocidad y los materiales disponibles.

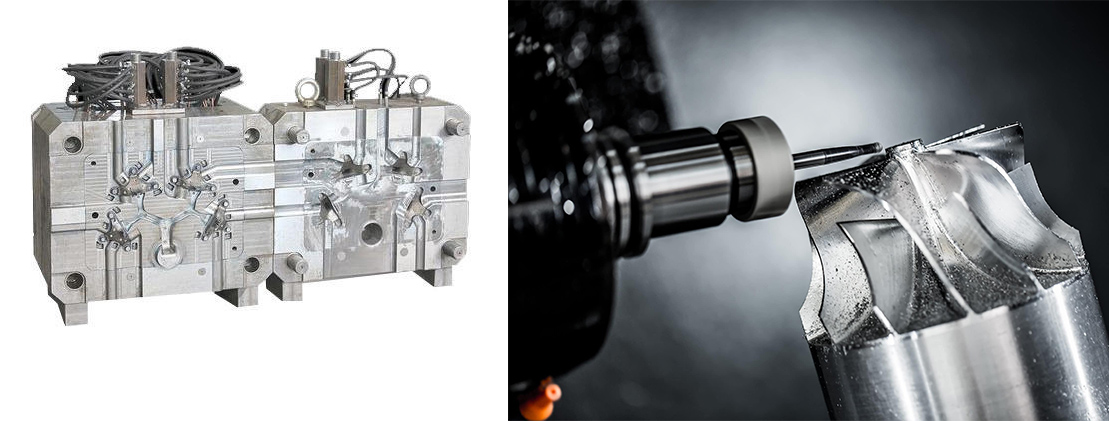

La fundición a presión implica obligar a que el metal fundido se vierta en un molde, que también se conoce como matriz. El molde suele estar hecho de acero y el proceso se utiliza cuando se desean piezas con geometrías complejas y tolerancias estrechas. La fundición a presión se aplica principalmente en metales como aluminio, zinc, magnesio y sus aleaciones, así como en cobre. El proceso permite la formación de piezas metálicas complejas y precisas en un tiempo relativamente corto; Ideal para producción en masa.

En la fundición a presión, los moldes generalmente están hechos de material de alta resistencia. El metal con la forma deseada se inyecta a gran presión en la cavidad del molde. Donde se enfría y endurece. Una vez que el molde se ha enfriado, la pieza se libera del molde mediante limpieza de precisión de recorte o incluso otros procesos.

La fundición a presión es famosa por su ciclo corto. El uso de moldes facilita la producción de piezas en grandes cantidades, lo que lo convierte en el más rápido de producir. El tiempo total del ciclo varía desde unos pocos segundos hasta un par de minutos, dependiendo de la geometría de la pieza y del material que se utilice.

El proceso es económico cuando se utiliza para fabricar muchas piezas a la vez o con una gran capacidad de producción. En general, el costo de la fundición a presión es menor que el costo de otros procesos debido a la reducción del costo por unidad con el volumen de producción. Una vez creado el molde, las piezas siguientes se fabrican a un coste adicional por pieza relativamente bajo.

Además, la fundición a presión permite fabricar piezas con formas muy complicadas que no se pueden fabricar fácilmente con medios convencionales. Las características detalladas y los diseños intrincados se pueden lograr con un espesor lo más fino posible. Esto hace que la fundición a presión sea adecuada en industrias como la del automóvil, la electrónica y la aeronáutica, donde estas características son más necesarias.

Los componentes fabricados mediante fundición a presión normalmente se caracterizan por acabados superficiales suaves y tolerancias pequeñas, por lo que necesitan poco procesamiento posterior. Esta precisión y delicadeza son útiles en muchas industrias donde el producto final debe diseñarse según ciertos estándares o donde debe cumplir ciertos estándares de rendimiento.

Las piezas fundidas a presión son uno de los componentes más populares debido a sus considerables características mecánicas, incluidas su resistencia y robustez. La presión empleada durante la fundición mejora la densidad de la microestructura del material, dando al producto final buena resistencia y durabilidad frente al desgaste y la corrosión.

Este proceso solo es adecuado para una selección particular de materiales; comúnmente se prefieren los materiales no ferrosos, que incluyen metales como aluminio, zinc y magnesio. Aunque estos materiales son populares en diversas industrias, la fundición a presión tiene algunas limitaciones, particularmente en el caso de metales con altas temperaturas de fusión, como el acero o el titanio. Esta limitación puede convertirse en una desventaja en algunas aplicaciones donde se necesitan dichos materiales.

Principalmente, se crea la matriz (molde), ya que desarrollar piezas complejas puede ser costoso. El molde suele estar formado por acero de alta resistencia, por lo que tiene un rango alto para la configuración inicial. Por este motivo, la fundición a presión es relativamente cara para la producción a pequeña escala, debido a este desembolso inicial. Pero cuando se trata de la escala de producción, el costo por unidad del producto se reduce y se vuelve asequible para grandes cantidades.

La fundición a presión normalmente se asocia con la producción de componentes con buena precisión y calidad; sin embargo, es difícil lograr una tolerancia fina. Si la tolerancia es extremadamente precisa, es posible que se requieran operaciones adicionales para perfeccionar la pieza de trabajo. Esto puede aumentar el coste total y el tiempo de fabricación de estos productos, especialmente las piezas pequeñas y complejas.

A pesar de la alta eficiencia del proceso de fundición a presión, el producto puede presentar problemas como la porosidad de las piezas moldeadas. Puede suceder si un metal fundido no logra cubrir completamente la cavidad del molde o si se realiza una ventilación deficiente, insuficiente o inadecuada en el molde. Sin embargo, este tema no tiene mayor importancia, pero sí afecta el rendimiento y el estándar del producto terminado, especialmente en aplicaciones de alto rendimiento.

Realizar cambios en los diseños de piezas en un molde suele ser engorroso y costoso una vez que se ha desarrollado un molde para ese diseño en particular. Dado que la formación del molde o la modificación del existente puede llevar tiempo y dinero, la fundición a presión es relativamente rígida en comparación con el proceso de mecanizado CNC, donde se pueden realizar modificaciones fácilmente durante el proceso de fabricación.

Mecanizado CNC (Control Numérico por Computadora) Se refiere a un proceso de fabricación donde el movimiento de las herramientas es comandado por programas de computadora. Debido a su flexibilidad, se utiliza comúnmente para producir piezas que requieren un tamaño y forma específicos. Los aparatos utilizados en el mecanizado CNC, como fresadoras, tornos, enrutadores y rectificadoras, están controlados por un programa de computadora para transformar la materia prima en un producto compilado. Este proceso puede adaptarse a una amplia variedad de materiales como metales, plásticos, madera y compuestos.

La máquina CNC funciona controlando el movimiento de las herramientas de corte en varias direcciones, que incluyen tres, cuatro o cinco direcciones para taladrar, fresar, tornear o esmerilar. El diseño de la pieza está en formato digital, normalmente se carga un archivo CAD en la máquina CNC donde el software CNC lo interpreta y los movimientos se crean y ejecutan con precisión. Esta automatización garantiza la precisión y la estandarización de todo el proceso de producción.

Las máquinas CNC pueden funcionar con precisiones de unas pocas micras (milésimas de mm) y, por lo tanto, son adecuadas para aplicaciones sensibles a la precisión, como aplicaciones aeroespaciales, automotrices y médicas. Otra ventaja del mecanizado CNC es que se puede repetir varias veces y aún así el resultado será casi idéntico gracias al control preciso por parte de la computadora.

El mecanizado CNC puede trabajar con prácticamente todo tipo de materiales, ya que es muy capaz en lo que respecta a los materiales que utiliza. A diferencia de la fundición a presión, que tiene una limitación en los materiales que se pueden utilizar, el mecanizado CNC puede adaptarse a todo tipo de materiales, como aluminio, acero, titanio, plásticos, compuestos y madera. Esta propiedad lo hace adecuado para su uso en diferentes industrias que requieren piezas fabricadas con diferentes materiales de diferentes características mecánicas y eficiencia.

El CNC ofrece un alto rendimiento de flexibilidad, especialmente en caso de cambio de diseño o modificación del producto. Dependiendo de la programación del software de las máquinas CNC, la personalización se puede realizar fácilmente sin pedir nuevos moldes o herramientas. Es por esta razón que el mecanizado CNC es ideal para la creación de prototipos, tiradas cortas o piezas únicas, como suele ocurrir con los productos personalizados. Es adecuado para componentes que tienen características complicadas o delicadas que podrían ser difíciles de mecanizar o muy costosas mediante fundición a presión.

El mecanizado CNC brinda la capacidad de diseñar formas complicadas y huecos y protuberancias estrechas que podrían ser imposibles de implementar con otros procesos como el moldeo por inyección o la fundición a presión. Gracias a la configuración perfecta del mecanizado CNC, el producto final puede lograr geometrías muy complejas, características como roscas, pasajes internos y radios estrechos con un gran grado de precisión.

En comparación con la fundición a presión, que necesita moldes costosos para la producción de una gran cantidad de piezas, el mecanizado CNC no necesita herramientas costosas para cada pieza. La mayor inversión en el mecanizado CNC es el tiempo que consume la máquina CNC y el costo de mano de obra, pero una vez que se crea el programa CNC, las piezas se pueden fabricar en poco tiempo con un costo ligeramente mayor. Esto hace posible que el mecanizado CNC sea más económico para producciones de lotes pequeños y medianos o donde los cambios de diseño son frecuentes.

Comparando el mecanizado CNC con la fundición a presión, el CNC es más barato para la producción de escala baja a media; sin embargo, no es tan rentable para la producción en masa. El costo por pieza en el mecanizado CNC puede ser relativamente alto porque cada pieza se mecaniza de manera diferente y requiere mucho tiempo. Esto hace que sea costoso para la producción en gran volumen de componentes simples que pueden producirse mediante métodos de fundición a presión.

La fundición a presión es generalmente más rápida que el mecanizado CNC en el sentido de que este último es más apropiado para la fabricación de un gran número de piezas. Las máquinas CNC pueden funcionar las 24 horas del día, los 7 días de la semana, pero el proceso de creación o eliminación de material, ya sea mediante corte, perforación o fresado, cada pieza se revisa en cada ciclo, lo que lo hace más lento que los rápidos tiempos de ciclo de la fundición a presión. En comparación con la fundición en arena, la fundición a presión es mucho más rápida, especialmente para la fabricación de gran volumen donde hay un alto rendimiento.

La razón es que el mecanizado CNC es un proceso de corte del material a partir de un bloque sólido (también conocido como "fresado" o "corte"), lo que genera un gran desperdicio de material, especialmente cuando se producen formas complejas. La materia prima normalmente se presenta en forma de grandes palanquillas o bloques y partes de estos se cortan durante el proceso. Esto puede llevar a una situación en la que se incurra en costes de materiales, especialmente cuando los materiales son caros, como el titanio o una aleación de alto rendimiento.

Si bien el mecanizado CNC puede crear piezas muy precisas, el tamaño de una pieza puede verse afectado debido a la capacidad limitada de la máquina. Algunos de sus componentes son de mayor tamaño; esto puede incluir el uso de herramientas especiales o debe dividirse en piezas pequeñas para girar, lo que requiere tiempo y esfuerzo adicionales. Esta limitación significa que el mecanizado CNC puede no ser tan conveniente para proyectos grandes/sobredimensionados o grandes/pesados como lo sería para otros métodos.

Todas las herramientas utilizadas en el mecanizado CNC se desgastan con el tiempo, especialmente cuando se cortan materiales resistentes o se fabrican muchas piezas del mismo producto. Este desgaste puede provocar una disminución en la precisión o la calidad del rendimiento de la herramienta y, por lo tanto, la necesidad de mantenimiento o reemplazo de la herramienta. Cuando se trata de piezas de alta precisión, el filo de las herramientas y el rendimiento pueden ser un factor crítico de éxito para lograr una alta calidad.

Fundición a presión: las aleaciones de aluminio, zinc, magnesio y cobre se utilizan mucho en esta técnica, pero también pueden trabajar con metales ferrosos. La selección de materiales también es más limitada que en el mecanizado CNC, pero el material proporciona resistencia y es liviano.

Mecanizado CNC: Mucho más diverso, el mecanizado CNC puede abarcar una amplia gama de materiales tan diversos como metales (aluminio, acero, titanio), plásticos, compuestos e incluso madera. Por este motivo, el mecanizado CNC se puede aplicar en diferentes campos y para usos específicos.

Die Casting: sostenible para producción de gran volumen. Una vez producido el molde, el tiempo del ciclo se puede minimizar en aproximadamente unos pocos segundos y es muy adecuado para aplicaciones de alta tasa de producción. En grandes volúmenes, el proceso es excepcionalmente productivo y entrega un producto uniforme en términos de cantidad, ya sea en miles o millones de piezas.

Mecanizado CNC: un poco más lento que la fundición a presión, especialmente cuando se trata de producción en masa. Se realiza de forma individual y dependiendo de cuán complejas sean esas partes, puede llevar desde varios minutos hasta horas por parte. Es más eficaz en producción de nivel bajo a medio, donde se necesitan productos en grandes cantidades pero con variaciones y un nivel muy alto de perfección.

Fundición a presión: la precisión es compatible, pero solo puede ofrecer un nivel medio de corrección y detalle en comparación con los del mecanizado CNC. Es ideal para aplicaciones con formas intrincadas pero es posible que no produzca un acabado superficial tan suave como el requerido por algunas aplicaciones.

Mecanizado CNC: proporciona mejor precisión y resolución para la pieza de trabajo, y puede contener dimensiones/tamaños muy pequeños y características finas. El CNC funciona mejor cuando existe necesidad de precisión, por ejemplo en la industria aeroespacial u otra parte médica donde el detalle y la precisión son primordiales.

Fundición a presión: este proceso es costoso al principio debido al alto costo del molde, pero la tasa por pieza es bastante baja cuando se fabrican grandes cantidades de piezas. Es más adecuado para la producción a gran escala cuando los costos se distribuyen entre una gran cantidad de productos.

Mecanizado CNC: No tiene costos de molde, sin embargo, el costo por pieza suele ser mayor y esto se debe al mayor tiempo de ciclo, especialmente para tiradas grandes. Las ventajas de la técnica son que es más barata para la producción de cantidades pequeñas y medianas y para la producción de piezas especializadas o de prototipos, pero un poco cara para la producción de grandes volúmenes. (cambió algunas palabras aquí también).

● Volumen de producción: cuando los requisitos de producción son altos, la fundición a presión es más barata, mientras que el mecanizado CNC es más adecuado para tiradas de producción moderadas.

● Requisitos de materiales: el mecanizado CNC es versátil en términos de uso de materiales, mientras que la fundición a presión se fija con una determinada aleación de material.

● Necesidades de precisión: el mecanizado CNC se utiliza para aplicaciones que requieren alta precisión y detalles finos, mientras que se prefiere la fundición a presión para tolerancias más simples en la producción en cantidad con una variedad muy baja de materiales.

● Producción en masa: Cuando se requiere la producción en masa de diferentes piezas con formas complejas en poco tiempo y a un costo razonable. La fundición a presión es más adecuada en tiradas de producción altas donde se evalúa el costo por pieza.

● Geometrías complejas: también es útil para fabricar piezas detalladas y con formas complejas a un ritmo rápido, especialmente para producciones de gran volumen con eficiencia y calidad.

● Tiradas pequeñas o personalizadas: el mecanizado CNC es adecuado cuando los requisitos de producción son pequeños o promedio, donde solo se van a producir unas pocas muestras o donde es probable que haya cambios frecuentes en el diseño.

● Piezas de alta precisión: cuando hay detalles finos que deben agregarse al interior del troquel, o hay líneas específicas que deben agregarse al exterior del troquel, o algunas formas que no se pueden crear en la fundición a presión porque del nivel de precisión exigido.

La fundición a presión y el mecanizado CNC son dos procesos bastante diferentes, y ambos tienen sus ventajas. La fundición a presión es más adecuada para un alto volumen de producción, herramientas económicas y diseños complejos y, al mismo tiempo, el mecanizado CNC es bueno para una producción baja a media, diseños complejos, piezas de alta tolerancia y precisión.

● Para producción en masa de gran volumen con diseños complejos: elija la fundición a presión.

● Para tiradas de producción pequeñas y medianas, piezas personalizadas o necesidades de alta precisión: opte por el mecanizado CNC.

En general; es necesario definir los requisitos de su proyecto, incluida la capacidad de producción, el material y la tolerancia. Un paso importante es comunicarse con los fabricantes u obtener una cotización para proceder. Seleccionar un proceso adecuado garantizará la excelencia en la productividad y la asequibilidad del proyecto.